Software

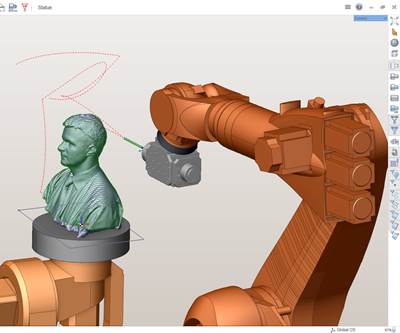

SprutCAM 12 Robot Enables Programming for Robotic Machining and Finishing

SprutCAM 12 features a more user-friendly interface and a 2D CAD editor integrated into the model page.

Read MoreFagor CNC Meets Aerospace Machine Shops' Accuracy Requirements

The CNC is seen as a complement to aerospace machine shops and those requiring extreme accuracy.

Read MoreCAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Read MoreCAM Software Optimized for Multitasking Machining

The updated GibbsCAM 13 provides a streamlined user experience, additional milling and turning capabilities and an enhanced G-code editor.

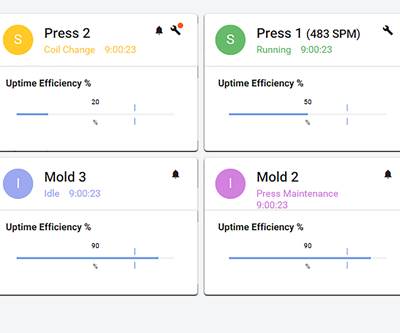

Read MoreData Software Helps Reduce Machine Downtime

Eastec 2019: According to the Wintriss Group, the data collected by ShopFloorConnect 6.0 can help reduce machine downtime by as much as 70 percent.

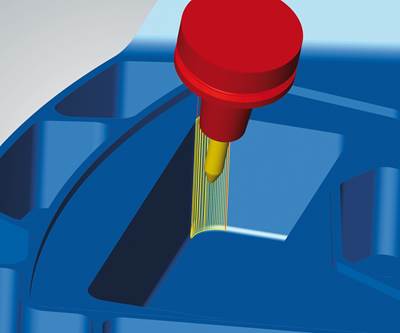

Read MoreCAD/CAM Suite Eliminates Cycle Recalculation Requirements

Eastec 2019: Open Mind’s HyperMill 2019.1 has a range of new features and enhancements including expanded modules, process optimizations, a new function for reducing calculation times, tool database flexibility, and CAD optimization.

Read MoreRetrofitting and Updating Keep Milling Machine CNCs on the Cutting Edge

After struggling to achieve higher feed rates and accuracy for complex milling of large compression molds, Century Tool and Gage Co. retrofitted Fidia CNC control systems onto existing machining centers.

Read MoreVertical Knee Mill CNC Now Also Configurable for Bed Mills

Eastec 2019: At Heidenhain’s booth, the Acu-Rite Millpwr G2 control will be highlighted, marketed as an easy-to-operate CNC for vertical knee mills.

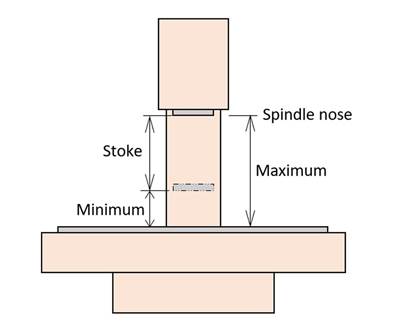

Read MoreChecking Cutting Tool Offset Values

A setup program can be used to test for overtravel issues before a workpiece is run, eliminating program verification delays.

Read MoreUnderstanding the Internet of Things

Part of the strangeness is this: There is not much to understand! Cheap sensors, fast connectivity, and data storage and applications in the cloud all come together to simplify certain kinds of automation needs. A band saw in the lab at Georgia Tech illustrates how manufacturers might put this to use.

Read More