Vertical Machining Centers

Video: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

WatchVideo: Machining Long Parts Through a Small Machining Center

Video from Chiron America demonstrates the company’s Multi-Profile System, which combines a machining center with in-feed and out-feed accessories so that the compact machine can mill and drill long parts.

WatchPrecise Die/Mold VMC for Roughing and Finishing Operations

With a 12,000-rpm, 20-hp, low-vibration IDD spindle and a structure designed for high damping characteristics, the NDV102A VMC provides high accuracy and reduced vibration, according to manufacturer YCM. The VMC’s 40" × 23.6" × 23.6" X-, Y- and Z-axis travels offer extra working capacity for larger die/mold requirements.

Read MoreMachining Complex Parts on a Five-Axis VMC

Makino’s F5-5XR VMC combines high-performance hard milling with multi-axis capability for increased accuracy, speed, flexibility and productivity.

Read MoreVMCs Feature Pallet Changers

The Quaser MV154 APC, which is a VMC that features 31.4" × 19.6" pallets, includes X-, Y- and Z-axis travels of 27.5", 19.6" and 22", respectively.

Read MoreThe 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

Read MoreFull Model Change for Vertical machining center Series

The NVX5000 series of VMCs from DMG/Mori Seiki has evolved from the NV5000 series as a result of a full model change.

Read MoreVMC for Crowded Shop Floors

Doosan Infracore’s DNM 400A VMC is designed for high productivity with precision tolerances, and built to fit crowded shop floors.

Read MoreDouble-Column VMC

Distributed by CNC Systems, Vision Wide’s SF series bridge mills feature additional Y-axis options of 47", 63" and 78". The X-axis selection ranges from 80" to 162" and the Z axis measures 31.5". The narrower Y-axis machine has roller linear ways on the X and Y axes for faster feed and rapid traverse rates.

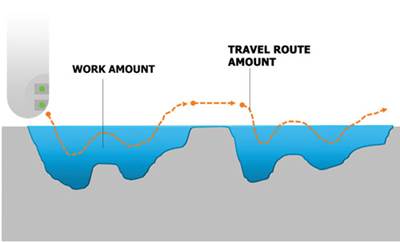

Read MoreStandard Software Addresses Common Machining Challenges

These low-cost VMCs come standard with a number of software features that enable them to compensate for machining’s inherent physical and thermal challenges.

Read More