Workholding

Dead Centers Feature Interchangeable Points for Fast Setup

IMTS 2018: Riten Industries’s Quick Point dead centers complement the company’s Quick Point live centers.

Read MoreWorkholding Technology Reduces Operations, Scrap, Labor

IMTS 2018: Blue Photon’s photo-activated adhesive workholding system is said to save time and money by reducing the number of operations, scrap and labor.

Read MoreCustom Design and Workholding Capabilities Improve Efficiency

IMTS 2018: Jergens is demonstrating its expanded custom design and build workholding capabilities.

Read MoreMechanical Unit Offers Lightweight, Compact Workholding Option

IMTS 2018: Tecnara is displaying the Kawata Touchdex, a fully mechanical unit that automatically indexes and synchronizes with NC programs.

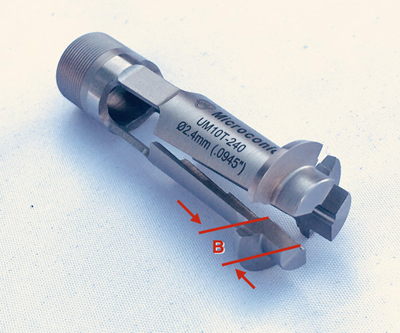

Read MoreCartridge Reduces Cycle Time, Enables More Subspindle Operations

IMTS 2018: Masa Tool’s Microconic push-type F201M10 cartridge pairs with its Microconic collets for concentricity within 5 microns (0.0002") in production use.

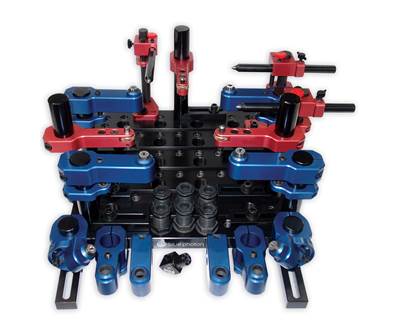

Read MoreWorkholding Systems Speeds Chuck Change-Over

IMTS 2018: Hainbuch’s CentroTex system facilitates fast and easy chuck changeover for manufacturers processing multiple parts of varying sizes that require various of clamping methods.

Read MoreOver-Grip Collet Designed for Holding Longer Parts

IMTS 2018: Masa Tool’s Microconic T-type over-grip collet features a longer gripping surface for holding longer parts.

Read MoreExpansion Clamps Secure Workpieces During Machining, Transfer

IMTS 2018: Pascal will display a variety of workhandling products designed for productivity and machining efficiency.

Read MoreHeavy-Duty Chuck Enhances Protection for Reduced Downtime

IMTS 2018: Pratt Burnerd’s 80" heavy-duty, three-jaw manual universal chuck has long master jaws with wiper blades to protect from metal shavings entering the chuck.

Read MoreSteady Rests, Work Rests Support Range of Applications

IMTS 2018: Kitagawa NorthTech will be featuring its complete line of turning steady rests and grinding work rests.

Read More